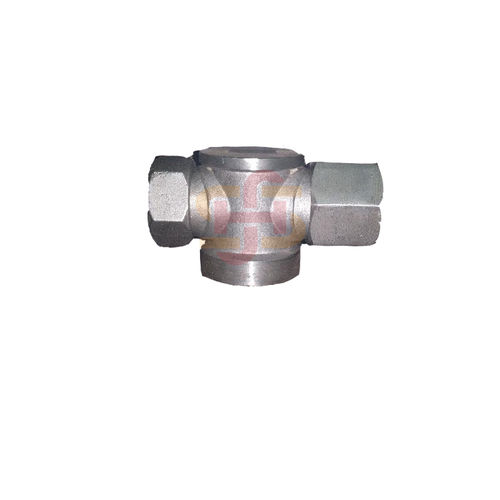

Agarbatti Machine Rocket Nozzle and Cup Die

300 INR/Set

Product Details:

- Condition NEW

- Quality High grade metal, precision engineered

- Feature Long life, rust resistant, wear resistant, easy fitting

- Production Speed Depends on machine; supports up to 200 kg/8 hr

- Capacity Suitable for high-speed production

- Weight (kg) 0.25 kg to 0.5 kg (approx.)

- Type Rocket Nozzle and Cup Die

- Click to View more

X

Agarbatti Machine Rocket Nozzle and Cup Die Price And Quantity

- 300.00 - 300.00 INR/Set

- 300 INR/Set

- 5 Set

- Yes

- Anti-rust coating

- High

- Individual box or polybag per set

- Helps form precise and uniform agarbatti sticks

- Compatible with most semi-automatic and automatic agarbatti machines

- CNC Machined

- Hardened steel/Alloy

- Polished

- For agarbatti making machine stick forming

- Easy to clean and maintain

Agarbatti Machine Rocket Nozzle and Cup Die Product Specifications

- NEW

- Not applicable (used for nozzle/cup die, not finished stick)

- Standard size as per machine specification

- Silver/Chromed

- 0.25 kg to 0.5 kg (approx.)

- Long life, rust resistant, wear resistant, easy fitting

- Rocket Nozzle and Cup Die

- Depends on machine; supports up to 200 kg/8 hr

- 1.5 mm to 3 mm

- Suitable for high-speed production

- High grade metal, precision engineered

- Raw agarbatti stick type compatible

- Yes

- Anti-rust coating

- High

- Individual box or polybag per set

- Helps form precise and uniform agarbatti sticks

- Compatible with most semi-automatic and automatic agarbatti machines

- CNC Machined

- Hardened steel/Alloy

- Polished

- For agarbatti making machine stick forming

- Easy to clean and maintain

Agarbatti Machine Rocket Nozzle and Cup Die Trade Information

- 10 Set Per Day

- 1 Week

Product Description

We have been offering the best quality of Agarbatti Machine Rocket Nozzle and Cup Die which is preferred by thousands of customers. Our objective has been to offer highest class array. The orders are placed in bulk and they are fulfilled with ease. Our company has a smart infrastructure which helps us to manufacture Agarbatti Machine Rocket Nozzle and Cup Die in large quantity. We are delighted to see the current high reputation of our enterprise which depends on our high grade product supply.

Specification

- Rocket Nozzle Available: 85 MM / 90 MM / 105 MM

- Cup Die Available: 2.8 MM to 10.0 MM

Technical Specification

Brand | SHREE HARI |

Part Type | Rocket Nozzle & Cup Die |

Engineered for Precision and Durability

Manufactured using hardened steel or alloy and processed with CNC machining, the Rocket Nozzle and Cup Die deliver reliable stick formation for agarbatti makers. The polished finish and anti-rust coating further enhance its longevity and performance, supporting continuous high-speed production.

Universal Compatibility for Agarbatti Machines

This nozzle and die set is designed to fit most semi-automatic and automatic agarbatti making machines available in India. Its standard dimensions, easy fitting, and rust-resistant surface make it a versatile choice for manufacturers, suppliers, and traders.

Effortless Maintenance and Longevity

Thanks to its high-grade metal construction and polished, anti-corrosive surface, this product is easy to clean and maintain. The wear-resistant attribute allows repeated usage in industrial environments, reducing replacement frequency and operational downtime.

FAQs of Agarbatti Machine Rocket Nozzle and Cup Die:

Q: How do I install the Rocket Nozzle and Cup Die on my agarbatti machine?

A: Installation involves ensuring that the machine is off and following your machines specific fitting guide. The nozzle and die are designed for easy fitting and are compatible with most semi-automatic and automatic agarbatti machines, making the process straightforward.Q: What is the main benefit of using hardened steel or alloy for the nozzle and cup die?

A: Hardened steel and alloy construction provides high durability, rust resistance, and long service life, even in high-speed production environments. This ensures consistent quality and reduces operational downtime due to tool wear.Q: When should I replace the nozzle and cup die on my agarbatti machine?

A: Replacement is typically required when you notice inconsistent stick shape, reduced production capacity, or visible wear despite regular maintenance. The robust design allows extended use before needing replacement.Q: Where are these nozzle and cup dies sourced or available from?

A: They are widely distributed by manufacturers, exporters, importers, suppliers, and retailers across India. Individual packaging makes them easy to store and transport for local and national distributors.Q: What is the process for cleaning and maintaining the Rocket Nozzle and Cup Die?

A: Cleaning is easy due to the polished, anti-rust coated surface. Wipe down after use with a dry cloth and periodically check for residue. Regular cleaning sustains performance and prevents build-up that could affect stick formation.Q: How does using this nozzle and cup die improve agarbatti stick quality?

A: Precision CNC machining and high-grade metal construction provide uniform stick diameter and shape, supporting raw agarbatti stick production between 1.5 mm to 3 mm diameter. This helps deliver consistent, market-ready products.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS